Processing methods

Electrolysis equipment with the help of the electrode discharges arcing electrical leads to the desired shape of the metal decay. Such equipment is usually used for: mold matrices production, broken taps burn, wedge formation, etc.

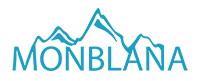

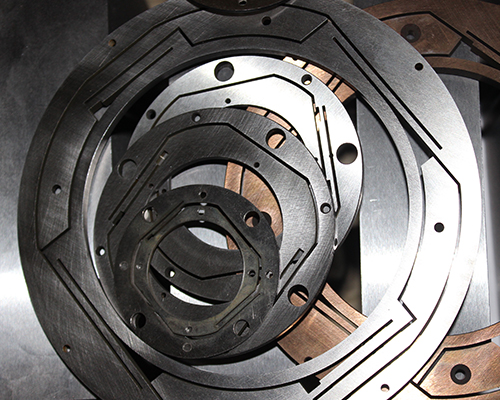

Electric erosion cutting with the wire

It is the highest precision intelligent machine. Machining accuracy of manufactured products have only 0,002mm error. It is possible to make 30 degrees holes and contours.

Turning

Company’s turning machinery consists of modern CNC machines and universal turning centers. Thanks to the programmable lathe with active instruments – we can offer a very accurate and fast production time.

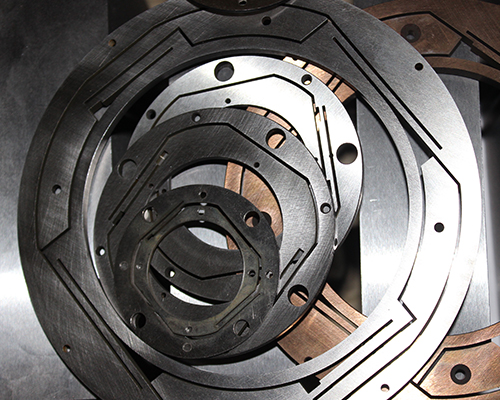

Milling

Our mill machines base consists of CNC and universal milling machines. We have the ability to supply small-scale, multi-serial and serial-production. We can produce larger size products (800×1100). Applying software SolidCAM with Imachining ensures extremely fast processing.

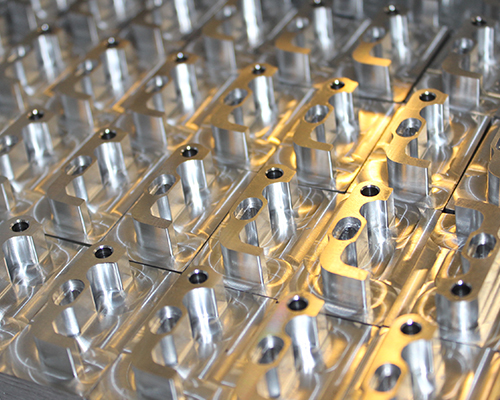

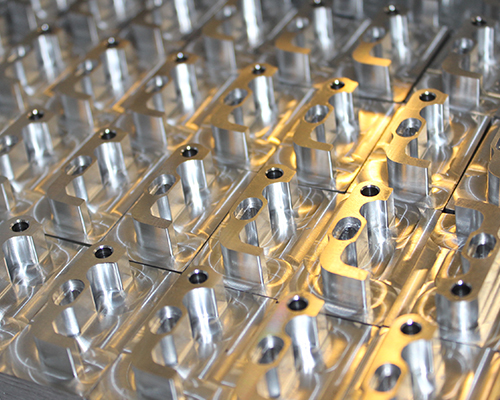

Casting and molding of plastic

We design and manufacture different shapes for molding. At the same time we are able to offer molding of plastic. It can save you time by offering forms of production and casting in one place. In cooperation with the customer we always find the most favorable conditions and the decisions on production and prices. We have injection molding machines capable of casting a variety of plastic parts from the body to serious configuration products. On our works we apply guarantees.

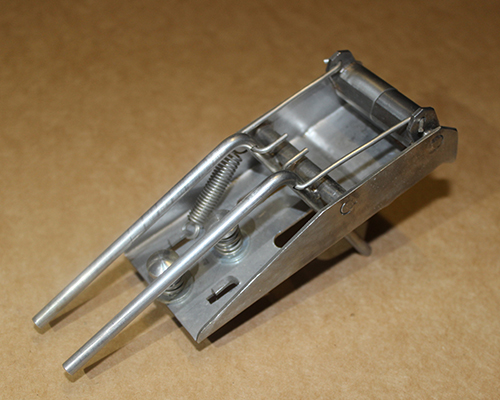

Stamp manufacturing, cutting and folding

From designed and manufactured stamps, we perform stamping and folding operations. For stamping works we use stamping press with up to 40 tons wieght. We punch and bend different types of metal.